Information & Application

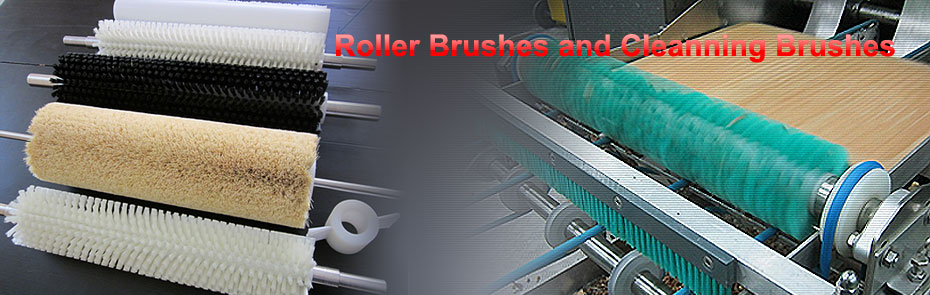

Custom stapled set tufted brushes manufactured to customer specifications

Stapled shapes include flat, strip, rotary, wheels, and discs

Infinite arrangement of brush patterns & layouts, sizes and styles

Plastic, wood, rubber, leather, solid block or core materials

Plastic placed over aluminum, steel or stainless steel cylindrical cores

Synthetic, natural bristle or wire fill materials

Products Information about Stapled Set Brushes

Stapled set tufted brush construction provides consistent product quality and reliability. The versatility of brush patterns, fill material choices, solid block or core materials available offers numerous design capabilities and options compared to any other brush construction. Tanis Incorporated offers a full range of fill materials including synthetics, natural bristle, wire and abrasive nylon. Solid block and core materials most commonly selected are wood and plastics including polyvinyl chloride (PVC), polypropylene, high-density polyethylene, ultra-high molecular weight (UHMW), ABS and delrin. Flexible materials like soft, flexible polyvinyl chloride and urethane are also available. Flexible body materials allow you to bend the brush around a corner or radius. Block shapes, materials and designs can be combined to develop a tailor-made product for your application.

Stapled brushes consist of a series of individual tufts of fill material inserted into a drilled hole in a solid block of plastic or wood. The tufts of material are secured to the block by a wire staple. Stapled set brushes are made with a variety of hole or tuft patterns to obtain the desired brush density and brushing effect. Hole patterns can be made with virtually any brush pattern. The function of the brush application and fill material size determines the density and size of the tuft holes. The brush fill material is trimmed in the final processing stage to give the desired shape required.

Tanis Incorporated technical sales and engineering staff will guide you making your selections of fill sizes and materials along with the block or core materials required for the environment of the application. Please call, fax or e-mail our staff about your stapled set brush requirements. Standard nomenclature and applications are highlighted below for your convenience. Please use our experience to design and manufacture an innovative custom stapled set brush to solve your application problems.

Applications

As there are endless shapes, styles and configurations for stapled set brushes there are an equal number of applications for this brush construction. Specific applications for stapled set brushes include:

Cleaning plates in printing/processing developing machines

Guiding paper in sheet offset printing

Brush seals for doors, overhead garage doors and dock levelers

Transporting and separating paper and corrugated product

Clean conveyor belts

Positioning and transporting product on conveyor lines

Seals for product containment

Washing and cleaning glass

Wax and polishing fruits and vegetables

Packaging pills in the pharmaceutical industry

Texturing and waxing downhill and cross-country skis

Carpet vacuuming and cleaning

Labeling and cleaning plastic and glass bottles

Home

Home