Nylox® (Abrasive Nylon Brush Filaments)

- Abrasive grain extruded throughout the filament

- Good toughness

- Excellent fatigue properties

- Chemical resistant

- Moisture resistant

- Chemical resistant

- Heat resistant

- 90% bend recovery

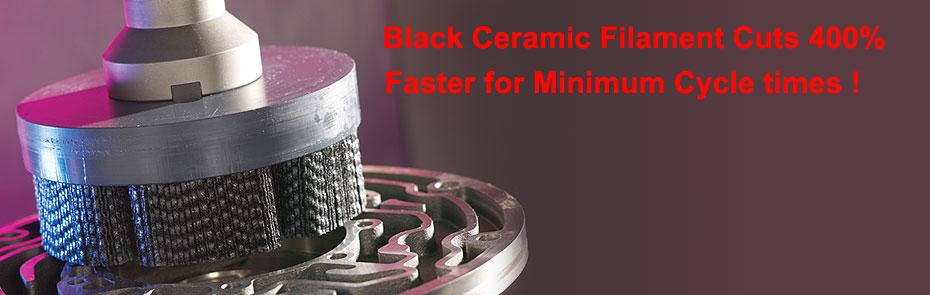

An abrasive filament that combines nylon and abrasive grit in a special formulation to deliver strength, stiffness even when wet, durability and chemical resistance. The abrasive grit is uniformly dispersed throughout the filament. Unique filament because the sharp cutting edges of grit can be held firmly against any surface no matter what its shape. As the brush moves against the surface, the cutting edges of the grit make good contact because the flexible filaments bend at various angles to fit the surface contour. Abrasive filaments are aggressive on the sides as well as the tips.

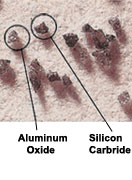

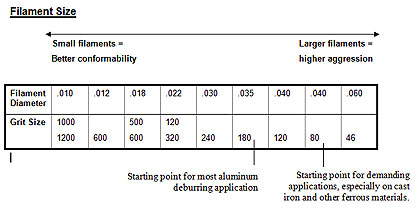

Abrasive filament is most often made with nylon 6.12 for use in wet or dry applications. Nylon 6 or Nylon 6.6 is suitable for dry applications and be treated against thermal degradation. Filaments are available in a broad combination of grit sizes (600 grit to 46 grit), loading and diameters (.012” to .060”). Grit loadings range from 20% by weight of grit to 40%. Abrasive filaments are impregnated with silicon carbide or aluminum oxide. Silicate is a fine abrasive filament with a .008” diameter and 1000 grit for micro-finishes.

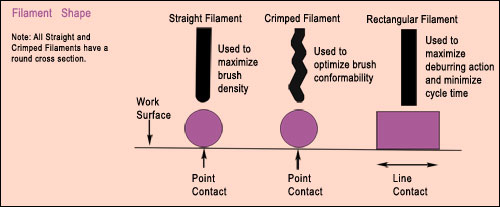

Filament Shape

Filament Size

Silicon Carbide

Silicone carbine

- Used in the majority of application

- Most cost – effective grain type

- Less than 0.1 % Iron Oxide and no free Iron

Silicon Carbide is a harder, sharper and more aggressive than aluminum oxide and is preferred for finishing ferrous metals. Silicon carbide is generally available in 500 to 46 grit and diameter ranges from .018" to .060".

Aluminum Oxide

- Aluminium Oxide

- Produces finish with more luster

- Use on soft and precious metals

- Prevents discoloration on certain alloys of titanium

- Use for wood application

Aluminum Oxide is more impact resistant compared to silicon carbide and is less likely to fracture and is preferred for finishing soft metals or other materials where a smooth finish is required. Aluminum oxide is generally available from 600 to 80 grit and diameter ranges from .012" to .040".

Silicate is a fine grade abrasive filament for fine finishing and cleaning. It is available in .008” diameter and 1000 grit for micro-finishes used most commonly in miniature twisted-in-wire brushes.

Home

Home