Fill Material Specification

Fill Material Specification

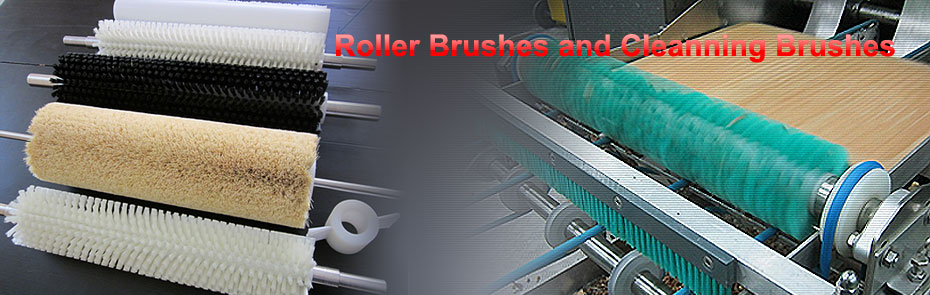

We are supplied of an industrial brush and we have served with synthetic, abrasive nylon, natural and wire bristles. The bristles are the working action of the brush and deserve plenty of attention in designing your industrial brush tool. Bristle characteristics vary for each type of material. Bristles may be stiff or soft, thick or thin, repel or absorb water, chemical and/or heat resistant, flexible to a greater or lesser extent, and resistant to bending or abrasion. Another factor determining bristle selection is the purpose the brush serves during use in the application. Bristles perform varying functions such as cleaning, sealing, guiding, applying pressure, wiping, cutting, abrading or polishing.

Other factors include brush density and length of bristle. Brush density appearance can be affected by the bristle being made with a crimp or level (straight) illustrated below. Crimped material has a wave in the bristle and provides a denser brush appearance. It produces a continuous and more even brushing action. Crimp is measured by amplitude, depth of the crimp, and frequency, number of crimps per inch. Level or straight bristles provide a lesser brush density appearance. The bristle length or trim is the exposed view and working strength of the brush. The surface of the bristles is uniform and flat. Tanis Incorporated technical sales and engineering staff will provide assistance with your bristle selection.

Kind of Fill Material

Home

Home